Model | GS-1325K |

X .Y Axis working area | 1300X2500mm |

Z-Axis working area | 200mm |

Repeatability | 0.025(+/-mm) |

Max Cutting Speed | 25000mm/min |

Rapid Traverse | 35000mm/min |

Spindle power rate | 4.5KW(air cooled) |

Controller | Markcut V8 |

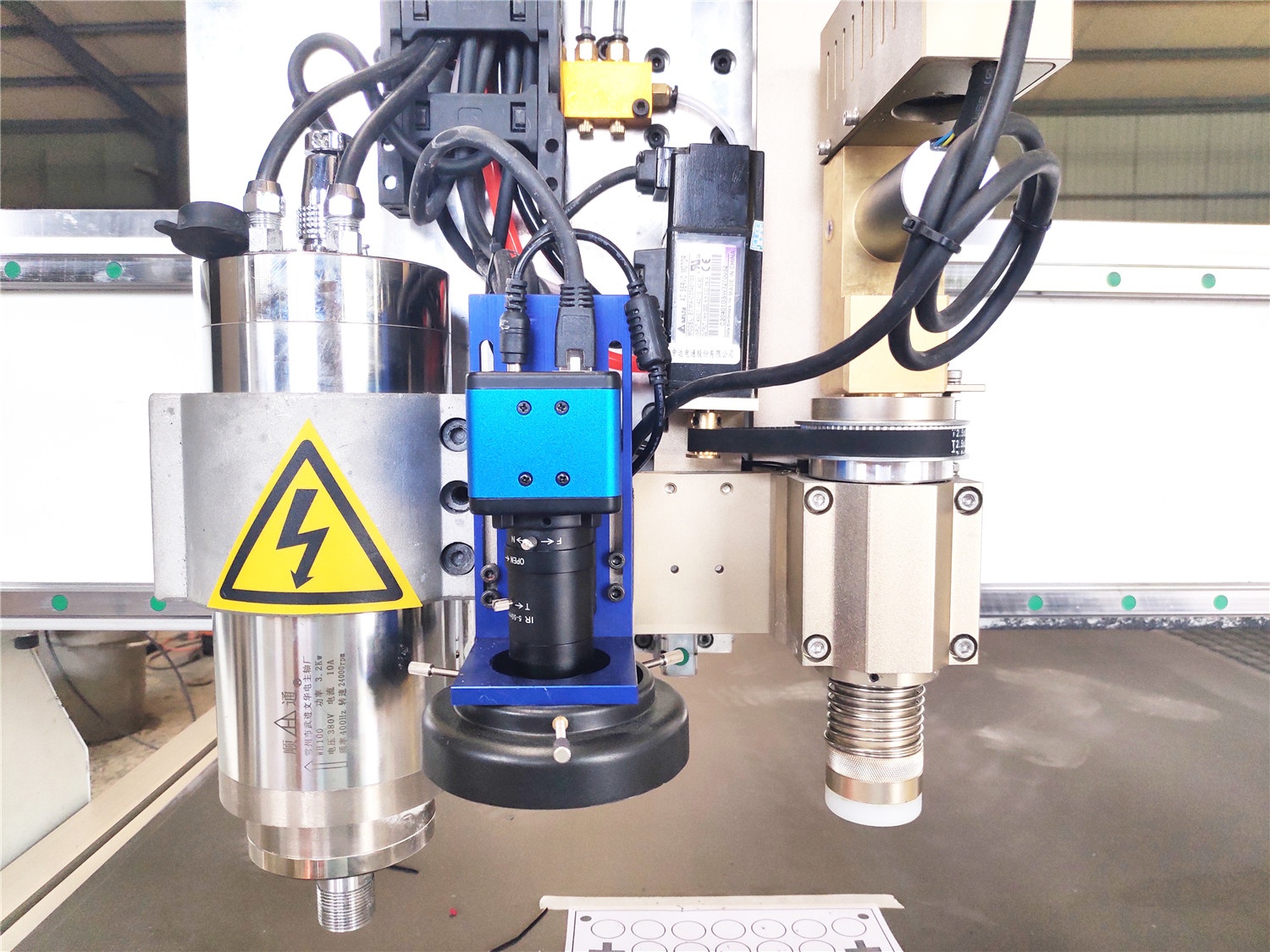

Accessory | CCD carema |

Spindle rotating speed | 0-24000rpm |

command | G code*.u00*.mmg*plt |

Work Mode | Hybrid servo motor (leashine) |

Transmission | X Y helical rack gear,Z ball screw |

Guide way | Linear guide way(hiwin) |

Power | AC380V/50~60Hz |

Main Features

1.Adopt heavy duty structure,CNC machinery center processing and forming,high strength and good stability;

2.More stronger cast iron stand to keep the machine working more stable;

3.Configure with high accuracy THK linear rail,high accuracy helical gear rack transmitting,more stability,higher precision;

4.Restart from power off,auto feeding,restoration,continue processing at break point.Support 9 coordinate setting,user friendly design;

5.Configured with 3 in 1 control system,quickcalculation,strong anti-interference ability;

6.Equipped with industrial camera,the probe is clear.High positioning precision;

7.Standard configured with 380V 5.5KW high speed water cooling spindle motor,high power high efficiency;

8.Independent control cabinet,stronger power and weak power separate,maintenance easily;

9.Be compatible with many CAD/CAM software like Type3/Artcam/Castmate/Probe/UG/Artgrave etc;

10.Standard with industrial matrix vacuum system;

11.Configure with manual oil lubrication system. Equipment maintenance is more convenient and quick.

Production Application

This series of machines are powerul, easy to use, reliable performance, widely used in high-effciency production of various billboards, pvc, acrylic, aluminum plastic board and other materials of three-dimensional carving and automatic cutting edge.

中文

中文 English

English